Myriad

Unit 5, The Quadrangle, Abbey Park Industrial Estate, Romsey, SO51 9DL, Hampshire, United Kingdom

PRODUCT SEARCH

BASKET (0)

You've come to the right place

Our team is best placed to ensure that you are quickly on the way to procuring the best quality parts. You can always trust Myriad as your go-to partner for all your transport refrigeration part needs.

Parts & Service +44 (0) 2380 71 01 68

Your Basket

Your basket is empty

22 July 2025

.png)

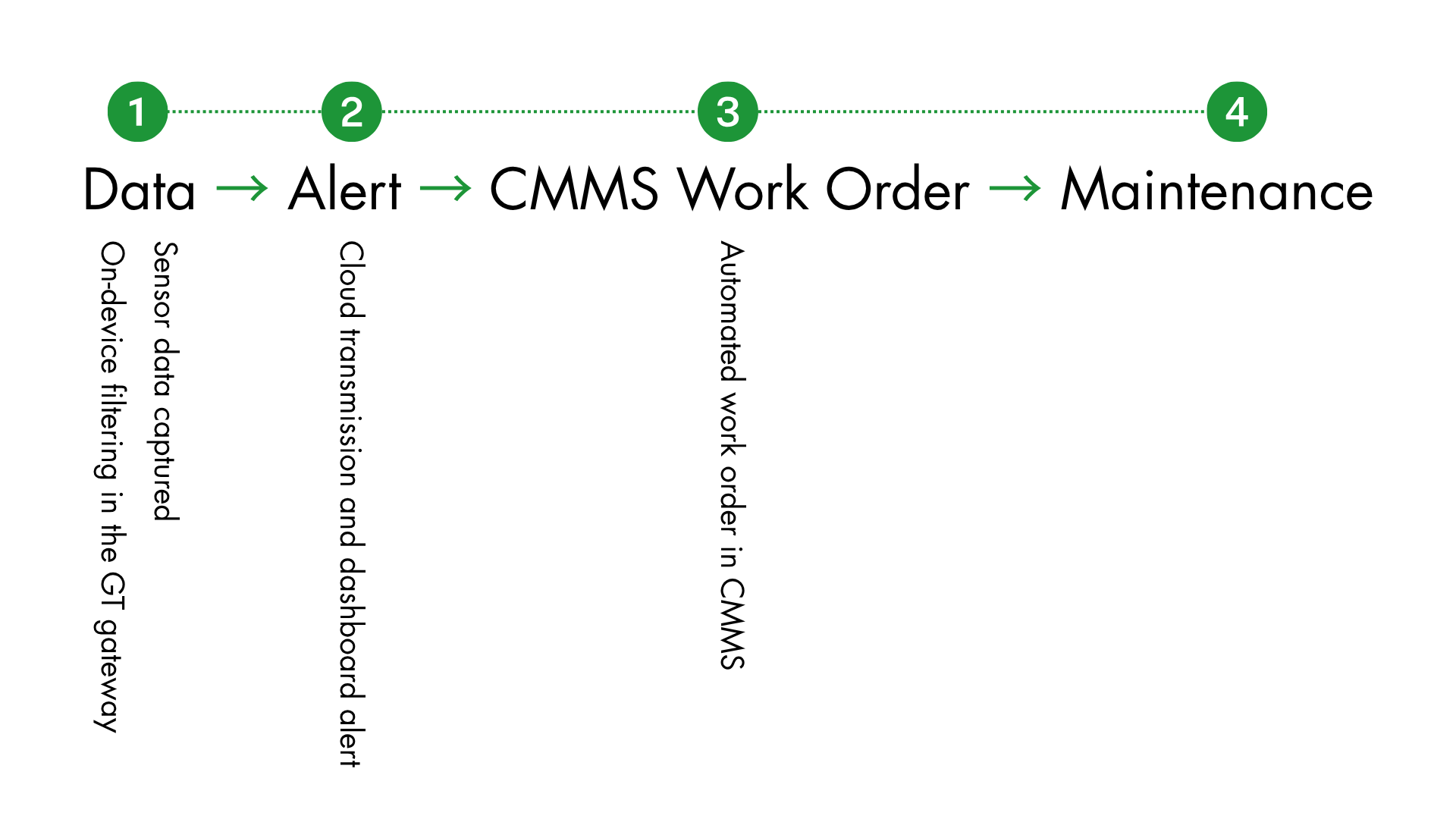

In today’s fast-paced cold-chain environment, unplanned equipment failures can bring operations to a standstill, jeopardising product integrity, inflating maintenance costs and eroding customer trust. Real-time telematics offers the visibility needed to catch anomalies early and transition from reactive repairs to predictive maintenance.

Reduced Unplanned Downtime

By continuously monitoring metrics such as temperature excursions and vibration levels, fleets can schedule interventions before minor issues escalate into full breakdowns.

Optimised Maintenance Costs

Maintenance based on actual equipment condition avoids both premature part replacements and emergency call-outs, maximising return on investment

Regulatory Compliance

Automated logging of temperature and runtime data supports audits under regulations like the FSMA (Food Safety Modernisation Act) and emerging F-Gas rules.

|

Metric |

Insight Provided |

|---|---|

|

Temperature Excursions |

Detects deviations beyond set thresholds—prevents spoilage |

|

Runtime Hours |

Informs optimal service intervals |

|

Vibration Analysis |

Flags mechanical wear before catastrophic failure |

|

Battery Voltage |

Ensures uninterrupted device connectivity |

|

|

|

|

|

|

ORBCOMM’s end-to-end cold-chain telematics solution was deployed across C.R. England’s 6,000+ refrigerated trailers and 1,500 intermodal reefer containers. In the first 12 months, they achieved:

These gains were driven by automated alerts on mechanical and decision-error conditions, plus seamless integration of telematics data into their dispatch and maintenance systems.

Speak with your Myriad Parts account manager about the Orbcomm telematics solution that best fits your fleet.

NEXT

WHY MYRIAD

OUR BRAND PARTNERS

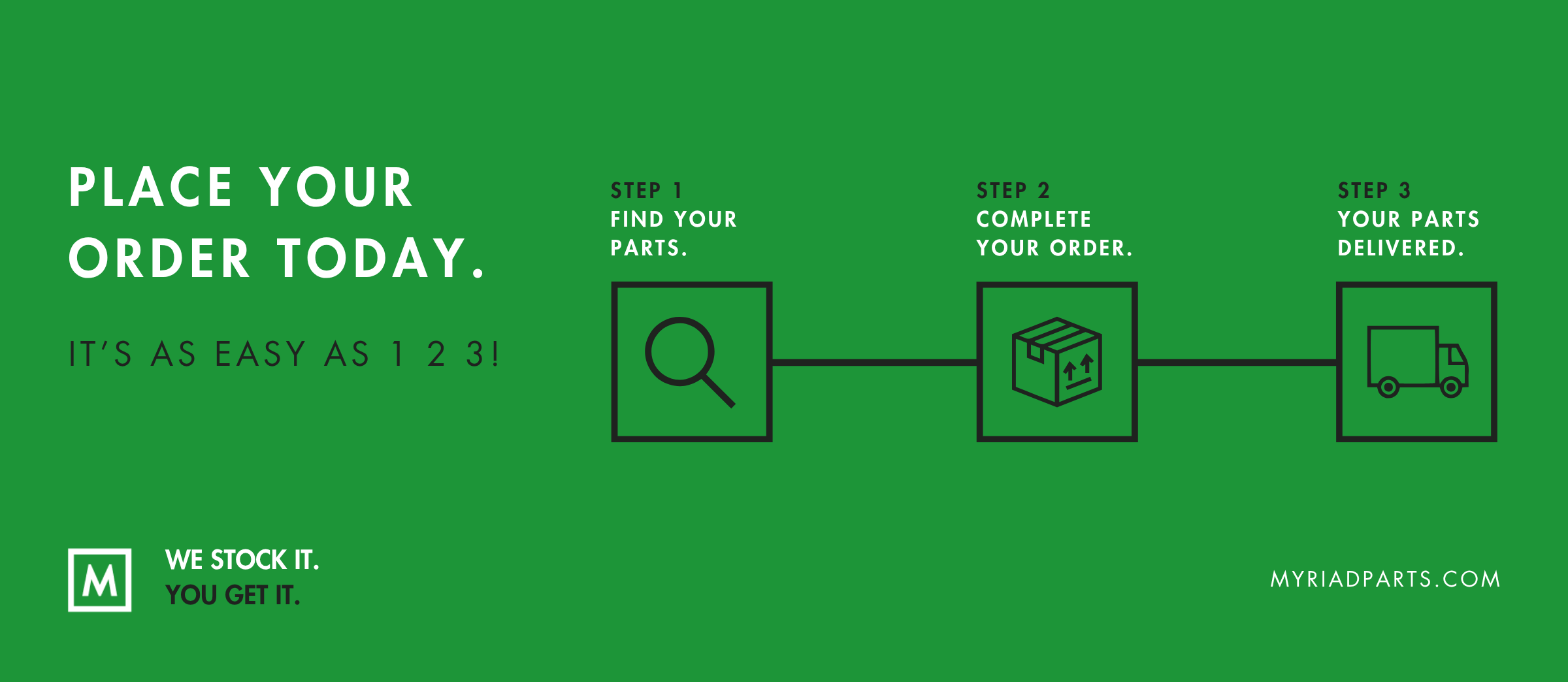

If you've not yet registered for an account with MYRIAD just click register to set up an account.

There were items in your basket from your previous session, would you like to Re-Add these items or Empty your Basket and Continue Shopping?

OR

Empty Basket & Continue